Chevrolet Sonic Repair Manual: Gears Cleaning and Inspection (Gen 2)

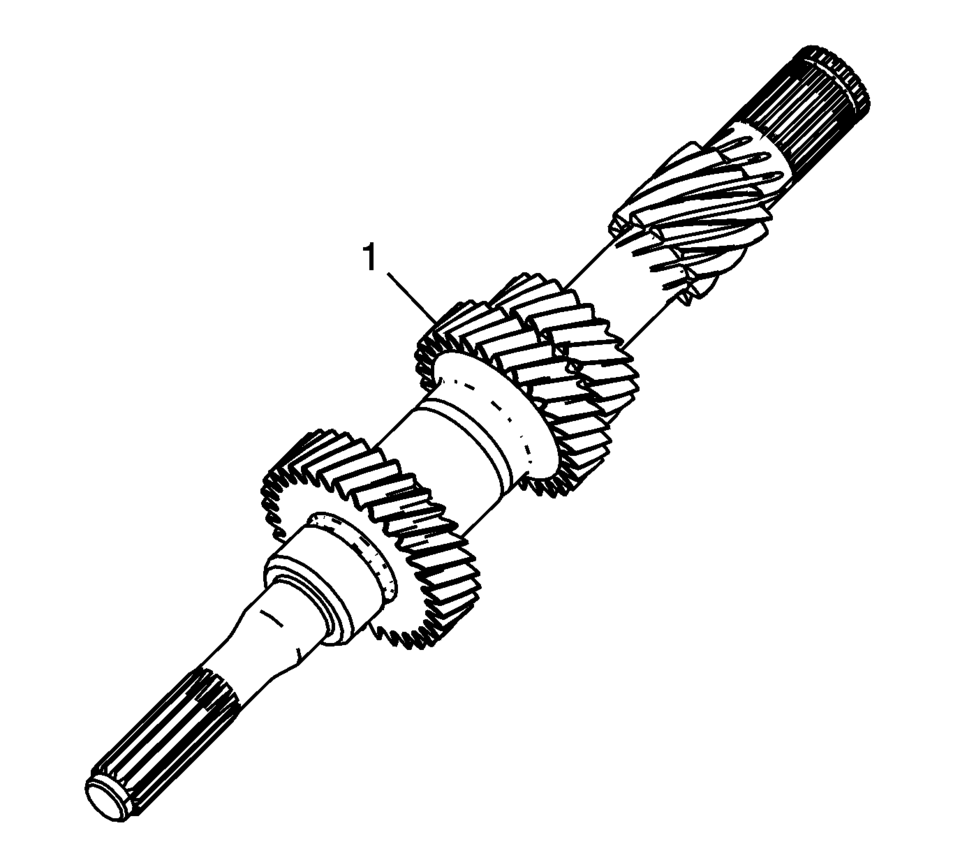

- Gears

-

- Clean the following gears in a suitable solvent and air dry all the parts.

Warning:

Wear safety glasses to avoid injury when using compressed air or any cleaning solvent. Bodily injury may occur if fumes are inhaled or if skin is exposed to chemicals.

- 1st Gear (1)

- 2nd Gear Assembly (4)

- 3rd Gear Assembly (3)

- 4th Gear Assembly (2)

- 5th Gear Assembly - Driven (5)

- 5th Gear - Driving (6)

- Inspect the gear tooth surfaces on all the gears for the following conditions:

- Cracks

- Pitting

- Nicks

- Chipped gear teeth

- High spots ?small shiny spots on the gear teeth mating surfaces

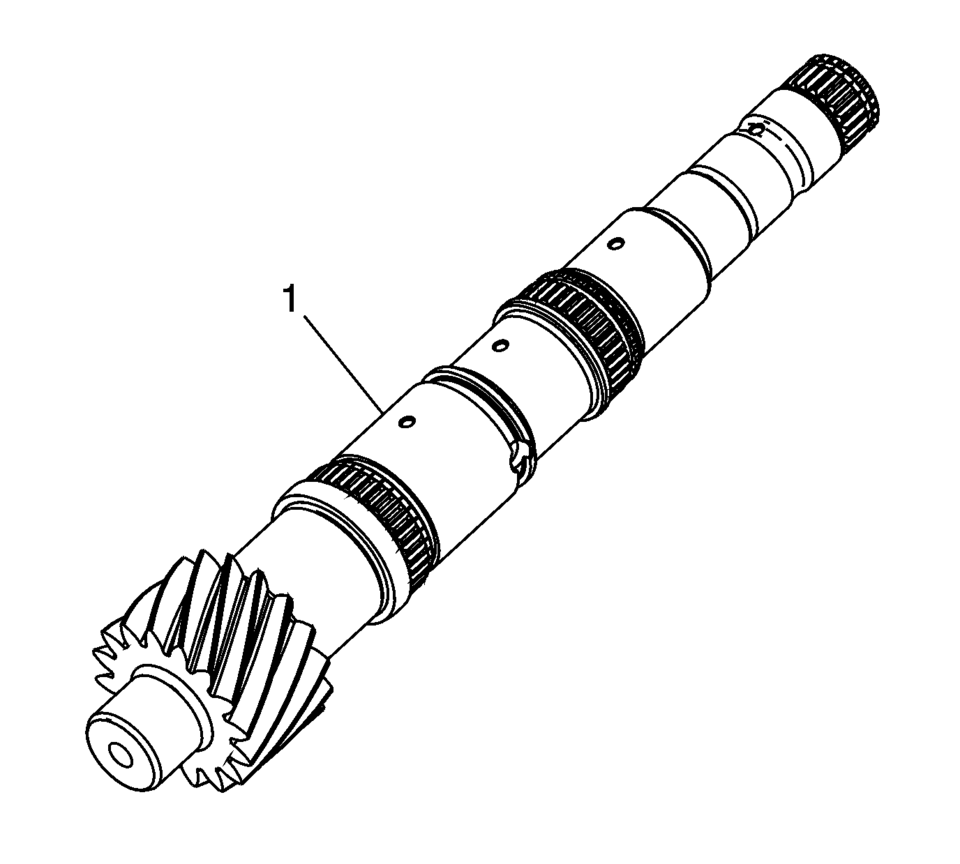

- Input Shaft

-

- Clean the input shaft (1) in a suitable solvent.

- Clean and air dry the oil gallery.

- Inspect the input shaft bearing surfaces for the following conditions:

- Wear

- Lack of lubricant

- Debris embedded in the oil grooves

- Brinelling

- Inspect the input shaft splines for wear or damage.

- Replace the input shaft if any of the above conditions are found.

- Main Shaft

-

- Clean the main shaft (1) in a suitable solvent.

- Clean and air dry the oil gallery.

- Inspect the main shaft bearing surfaces for the following conditions:

- Wear

- Lack of lubricant

- Debris embedded in the oil grooves

- Brinelling

- Inspect the main shaft splines for wear or damage.

- Replace the main shaft if any of the above conditions are found.

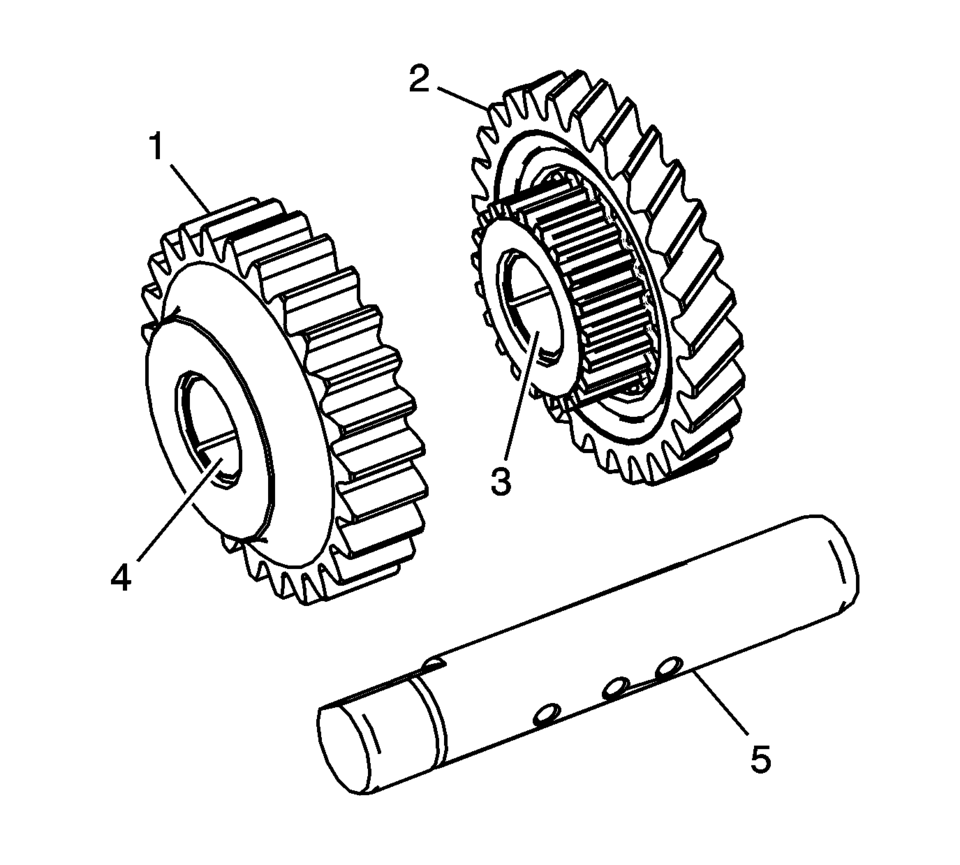

- Reverse Gears and Shaft

-

- Clean the reverse spur gear (1), reverse helical gear (2), and shaft (5) in a suitable solvent and air dry all the parts.

- Inspect the reverse spur gear bushings (4) and reverse helical gear bushings (3) for the following conditions:

- Excessive wear

- Scoring

- Pitting

- Replace the reverse gears if the bushings are faulty.

- Inspect the reverse gear shaft for the following conditions:

- Excessive wear

- Scoring

- Pitting

- Replace the reverse gear shaft if it is faulty.

Gears Cleaning and Inspection (Gen 1)

Gears Cleaning and Inspection (Gen 1)

Gears

Warning: Wear safety glasses to avoid injury when using compressed

air or any cleaning solvent. Bodily injury may occur if fumes are inhaled

or if skin is exp ...

Input Shaft Assemble

Input Shaft Assemble

Special Tools

J-840733 Driver

For equivalent regional tools, refer to Special Tools.

Note: Ensure the input shaft rear bearing retaining ring (2) is

placed on the input s ...

Other materials:

Front Wiper Blade Replacement

Windshield wiper blades should be inspected for wear or cracking. See the Maintenance

Schedule for more information.

Replacement blades come in different types and are removed in different ways.

For proper windshield wiper blade length and type, see Maintenance Replacement Parts.

Caution ...

Electronic Ignition System Description

Electronic Ignition System Operation

The electronic ignition system produces and controls the high energy secondary

spark. This spark ignites the compressed air/fuel mixture at precisely the correct

time, providing optimal performance, fuel economy, and control of exhaust emissions.

...

Camshaft Position Sensor Replacement

Camshaft Position Sensor Replacement

Callout

Component Name

1

Camshaft Position Sensor Fastener

Caution: Refer to Fastener Caution.

Tighten

6 Y (54 lb in)

2

...

0.0067